Home - Search - Browse - Alphabetic Index: 0- 1- 2- 3- 4- 5- 6- 7- 8- 9

A- B- C- D- E- F- G- H- I- J- K- L- M- N- O- P- Q- R- S- T- U- V- W- X- Y- Z

XLR43-NA-1

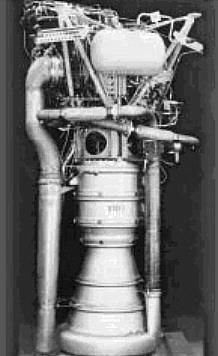

XLR-43-NA-1 Credit: Boeing / Rocketdyne |

AKA: Booster Engine One;NA-704 Mark III. Status: Development completed 1951. Date: 1949. Thrust: 333.00 kN (74,861 lbf).

In August 1945 the US Army Air Force defined requirements for post-war missile development in a classified document. In November 1945, they invited 17 aircraft systems manufacturers, to submit proposals for design studies of specific weapons. North American Aviation's Dutch Kindelberger, facing a reduction in employment from 100,000 to 6,500 employees as wartime aircraft production orders were cancelled, determined that missiles were the future and decided to make the necessary investments to win one of the contracts. He decided to found a corporate research lab, staffed with experts in such new fields as jet propulsion, rockets, gyros, electronics, and automatic control. William Bollay, the branch chief for development of turbojet engines in the Navy's Bureau of Aeronautics was identified as an appropriate leader of the lab. He arrived just in time to deal with the AAF request for proposals. Bollay decided to propose American development of the A9, a winged, boost-glide version of the German V-2, against the Army Air Force mid-range supersonic missile requirement. NAA received a letter contract in April 1946 for this missile, designated MX-770, with a range of up to 800 km.

North American began its rocket research was under way in the company parking lot, using a bulldozer scraper to protect adjacent parked cars from the inevitable exploding engines. They experimented first with a surplus Aerojet 4.5 kN motor. They then tried some small engines of their own devising, with up to 1.3 kN thrust. But as material came in from occupied Germany, it was obvious that the starting point would have to be the more advanced German technology. So in June 1946 Bollay proposed that North American first refurbish and test a complete V-2 engine system, to be provided by the government. This "Mark I" engine would be followed by redesign of the engine to American engineering standards and materials, followed by fabrication and testing of the "Mark II" American version.

By the end of 1946, two government-furnished V-2 engines arrived. In March 1947 North American rented a large tract of land in the western San Fernando Valley north of Los Angeles, in the Santa Susana Mountains, for use in testing of large engines. A rocket test center was built here, using $1 million of corporate funds and $1.5 million from the Air Force.

However as North American engineers tore down and reassembled the V-2 engines, it was clear that this Model 39 18-chamber engine was an engineering kludge, a prototype that was rushed into production because the ultimate planned engine was unavailable. By the end of the war the Germans had been testing a more advanced Model 39a single-chamber engine. So in the spring of 1947, it was decided to proceed immediately to design, construction and test of a new engine, the NA-704 Mark III, based on the German Model 39a. To assist in this, Bollay's team was free to draw on the expertise of the V-2 designers themselves, now working for the US Army - Wernher von Braun's team, including Walther Riedel, Hans Huter, Rudi Beichel, and Konrad Dannenberg. Dannenberg in particular had been intimately involved with the 'shower head' injector plate that was essential for the single-engine motor. Dieter Huzel, a close associate of von Braun, was hired by North American as a full-time employee in order to better coordinate work with the German team. In September 1947, preliminary design of the Mark III began, aiming at the thrust of the V-2 engine but with a weight reduction of 15 percent.

Nevertheless, construction of Mark II continued, in order to obtain experience. Detailed design had begun in June 1947 with first drawing release and parts fabrication coming in September. Meanwhile test in the parking lot continued of a 14.7 kN test engine on which a variety of shower-head injector patterns could be tested. In February 1948 ordered a complete redesign of the MX-770 missile to increase its range from 800 km to 1600 km. This was necessary purely for political purposes - when the US Air Force was split from the Army the year before, it had been agreed that the Army would handle missiles under 1600 km range, and the Air Force over that. The MX-770 was now an Air Force missile, and therefore had to have a range over 1600 km. To achieve this, North American decided to change the missile from the A9 pure rocket boost-glide vehicle to one that would use ramjet engines for sustained Mach 3 cruise. This approach had also been studied by the Germans for advanced versions of the A9. The rocket engine was now used for initial boost and to get the vehicle up to the supersonic speed necessary for ramjet ignition. But even with the more efficient ramjets, the entire vehicle would have to grow by 33% to meet the new range requirement. Accordingly the design thrust for the Mark III engine increased from the 249 kN of the V-2 to 333 kN.

Early in 1949, the first of three Phase II American-built versions of the Model 39 engine was completed. But by then North American was committed to the more advanced design. By late November of 1949, the first version of the Mark III engine was ready for testing at the new Santa Susana facility. Because it lacked turbopumps, propellants were pressure-fed from heavy-walled tanks. The North American team first ran the engine at 10 percent of maximum propellant flow for 11 seconds. However attempts for longer pressure-fed engine runs in December exhibited surges in combustion-chamber pressure (known as "hard starts") that were powerful enough to blow up the engine. Walther Riedel played an important role in introducing design modifications that brought this problem under control. In March 1950, this simplified engine first topped its rated level of 333 kN for four and a half seconds. During May and June, full-thrust runs, exceeding a minute in duration, went well.

Meanwhile, a separate developmental effort was building the turbopumps for the flight-weight engine. Late in March 1950, the first complete engine, turbopumps included, was assembled. In August, this engine fired successfully for a full minute at 12.3 percent of rated thrust. Late in October, the first full-thrust firing reached 310 kN for less than five seconds. However now a new problem emerged - rough combustion during the build up to full thrust. As a result, of the seven subsequent tests during 1950, only one in mid-November reached the engine's rated thrust level.

This combustion instability in the engine's single large thrust chamber had not been solved by the Germans before the end of the war, and they could not solve it now. However the North American engineers found a solution, and by March 1951 the problem of unstable combustion was under control. This marked an important milestone - the first time, the North American team had encountered and solved an important problem that the Germans could not solve. Combustion instabilities would recur repeatedly during subsequent engine programs, and the work of 1950 and 1951 provided North American engineers with several methods for work the problem.

In August 1950 the Air Force had directed another redesign of the Navaho based on North American studies for an intercontinental version. This 10,200-km range missile would use a separate, jettisonable booster. To achieve six times the range, the whole missile tripled in size. The Mark III engine was now just a way-station to the more powerful 530 kN engine required for the new Navaho. However, the Army had now directed von Braun's team to develop at utmost speed an 800-km range pure ballistic missile. With minor modifications, the Mark III would fit this requirement. So although the Mark III never went into production for the Air Force, its Army derivative boosted various versions of the Redstone tactical missile. And it would be this engine on the Redstone that would place the first American satellite in orbit and boost the first American into space.

In just three years of development, the North American team had delivered an engine that weighed less than half as much as the V-2's model 39 (668 kg versus 1126 kg), while delivering 34 percent more thrust. They had formed the corporate technology base for further American development of rocket engines. North American's rocket division, later dubbed Rocketdyne, would go on to be the preeminent American liquid engine rocket builder, building the engines that would take the first American to orbit, the first man to the moon, and power the Space Shuttle.

Country: USA. Launch Vehicles: Navaho SSM-A-2. Propellants: Lox/Alcohol. Agency: Rocketdyne. Bibliography: 524.

Back to top of page

Home - Search - Browse - Alphabetic Index: 0- 1- 2- 3- 4- 5- 6- 7- 8- 9

A- B- C- D- E- F- G- H- I- J- K- L- M- N- O- P- Q- R- S- T- U- V- W- X- Y- Z

© 1997-2019 Mark Wade - Contact

© / Conditions for Use